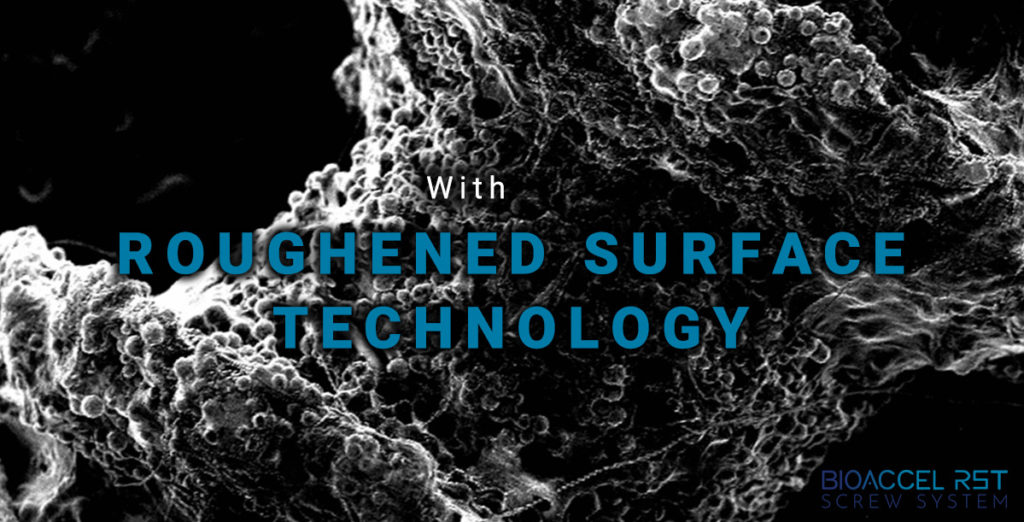

The image slider above shows a magnified image of a regular screw (left) without a roughened textured surface, as compared to one with roughened surface texturing portraying significant osseointegration. Scanning electron microscopy images of smooth surface (without) screws and roughened surface (with) screws. Study by: Jun Yang, Hong Cai , Jia Lv, Ke Zhang, Huijie Leng, Zhiguo Wang, Zhongjun Liu Published: April 30, 2014 https://doi.org/10.1371/journal.pone.0096179 Background image: https://journals.plos.org/plosone/article/figure?id=10.1371/journal.pone.0096179.g003

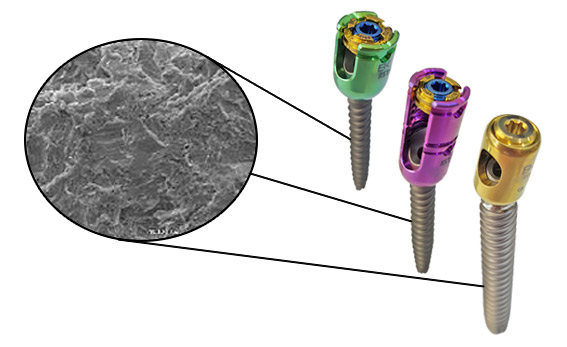

BK Meditech® USA has utilized years of data, and proven technology in the fields of dental implants and orthopedics, and has combined it with our own manufacturing capabilities, to position us in the forefront of implants as leaders in the field of roughened surface technology. BK MediTech® USA‘s pioneering screw technology in the field of complex spine, trauma, and minimally invasive spine, called BioAccel RST™ (Roughened Surface Technology), applies our proprietary methods of resorbable blast media (RBM) to achieve highly textured screw system surfaces. Through the application of our unique high temperature/high pressure method, we have created a special implant surface treatment using a Hydroxyapatite based biological accelerant which impregnate micro-particles into the surface of the titanium floor of our screw systems using a high strain blasting technique to achieve a remarkable surface roughness on a microscopic level. The screw systems are then passivated, and the blasting media is removed. This eliminates any issues of flaking off of the implant as in the additive process.

The image above portrays a magnified image of BioAccel RST™ roughened textured surface.